Conference keynote speaker, Dr Gregg Munshaw – Pinnacle Ag Research’s Chief Scientist & Director of Agronomy from the United States – presented vital advice to growers about – Getting More for Less. In today’s environment where costs are rising, and budgets are tightening the message was loud and clear – adapt to the changing environment. Katie Fisher reports.

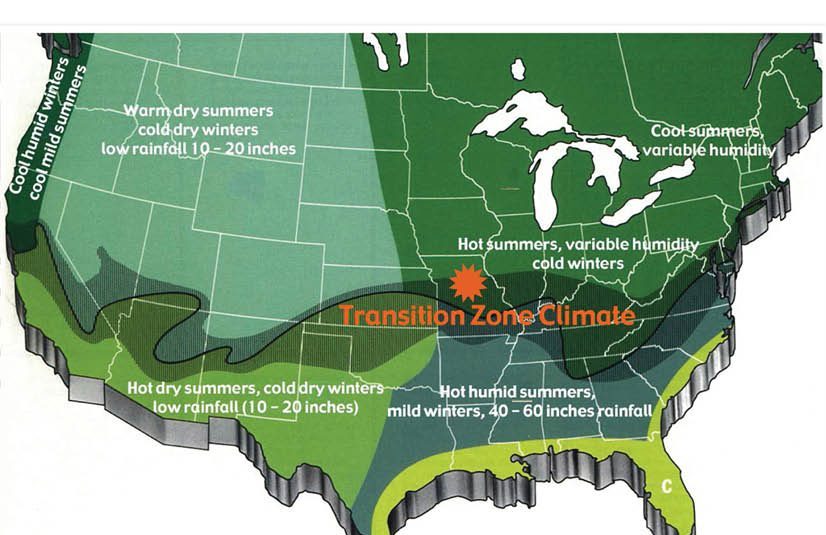

Dr Gregg Munshaw’s works for the parent company that owns Mountain View Seeds (MVS). He also does private research for MVS and other prominent seed companies (such as Syngenta, Bayer and BSF) to test which turf works best in the United States’ (US) Transition Zone Climate (see Figure 1 below).

The star on the Figure below indicates where Gregg works, right in the middle of the US – Missouri – where you can grow both warm and cool season grasses. The climate also allows you to test extremes for both types of grasses. North of Missouri, the climate has a moderate summer and very cold winters. The south experiences extremely hot summers and moderate winters. The Transition Zone is the only place on the planet where we can grow both grasses under the same conditions – therefore, a great place to trial grasses!

Figure 1: United States’ Transition Zone Climate.

COSTS RISING BUT BUDGET TIGHTENING

In the farming world, all costs are rising (fertilisers, chemicals, fuel and the list goes on) but budgets are predominately staying the same or getting tighter. It’s almost like COVID hit, and the World went crazy!

“So how do you maintain profitability while costs are sky rocketing? Are you coping or adapting?” Gregg asked growers at the conference.

“Can you review the areas of your business where you could cut back on in terms of work or budget?”

Gregg explained that such areas could include:

LABOUR

Can all tasks be accomplished at the same level with less staff?

Gregg stressed to be “… careful when reviewing this area, as quality and production could suffer”.

First ask …

- What gets sacrifice? Work quality on the farm in terms of mowing / harvesting etc… which could impact the paddocks.

- Less frequent mowing may mean the turf is harder to lift and because the quality is down the turf could be harder to sell.

PESTICIDES

Can usage be managed better and reduced?

- Can post-emergent applications be made rather than preventative pesticides?

- If the weed/seed bank is not aggressive, can you only follow-up with a pesticide if required?

- However, if you do have weed and disease pressure it may be harder to manage.

CULTURAL PRACTICES

These are an important part of production management, especially due to the use of heavy machinery on paddocks.

Ask … are you aerating/thatching?

- Thatch – promotes disease and pests.

- Harder surfaces promote poor plant development and can lead to thin turf growth.

- An aerating tip – if you can force your knife blade into the soil with just your thumb it probably is not compacted enough to aerate – however, if you can’t get the knife blade in, you need to aerate!

FERTILISING

Ask … can you cut back on fertility? Many paddocks are over-fertilised.

- For instance, Couch does need fertilising as quality can fall if it is not fed enough.

- Sometimes we are applying so much fertiliser and elements that are already bountiful in the soil, therefore soil testing is so important. For about $100 you can get a lot of valuable information from the results of a soil test and then understand what you should be applying and at the right rate.

GRASS VARIETY

Today new genetics are starting to change the Turf World – as we are seeing grasses that can do more for less, they are prettier, use less water as well as nutrients.

What should we do …

- Move to species or cultivars which have improved stress tolerance and recovery

- Growing varieties that require reduced inputs can save you money, and you can market the same savings to the end user.

- It will take some time to convert over to new material but in the long term the cost saving could be productive – analyse what the return will be on the new grass and what the future market is dictating.

MISCELLANEOUS PRODUCTS (PGRS, BIOSTIMULANTS, ETC…)

Today, many products on the market have little or no data to help you ascertain production.

- They may reduce mowing – but does the cost of the product outweigh the cost of mowing?

- Be wary of what’s on the market – “snake oil” for example, a lot of “thatch buster” products. Remember that the only thing that really helps thatch is top dressing, vertical mowing, aeration and getting the microbes to work the soil.

- Always review if the added cost of a PGR product is going to be effective – ascertain if there is any visual or quality differences (don’t just take a reps word for it).

NITROGEN

Turf Sprigging rate vs Nitrogen (N) application rate?

People think more is better! But is it?

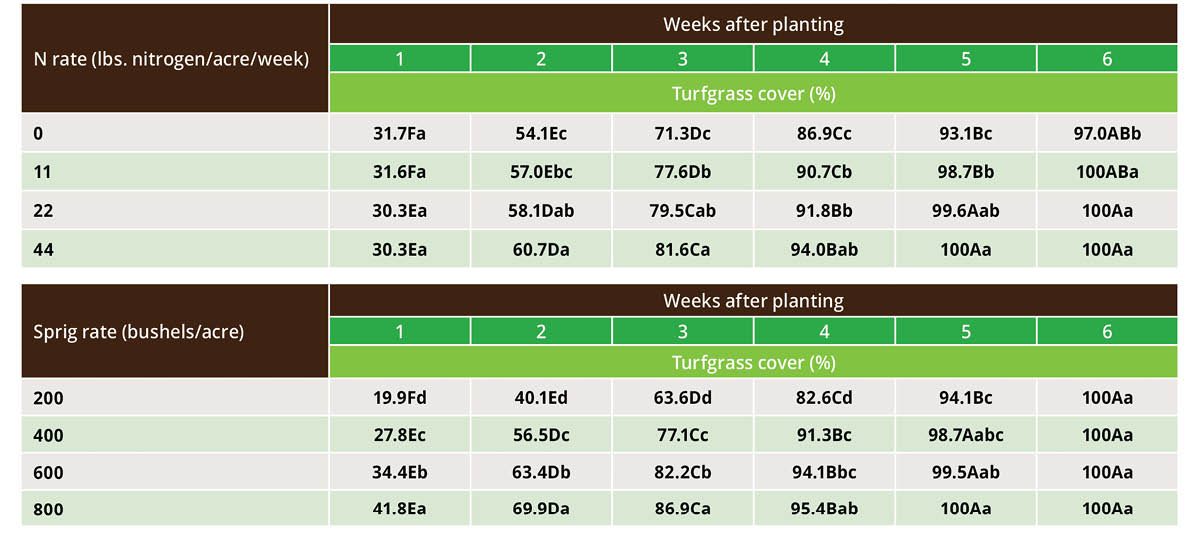

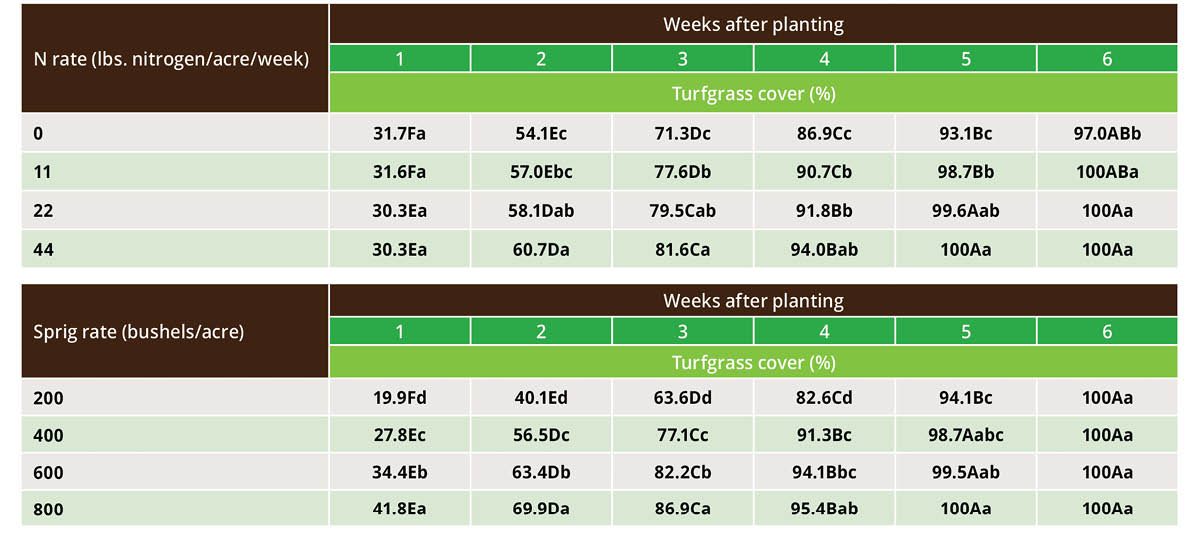

Gregg recently completed a study, with four other Universities across southern US, where turf was planted out at different sprigging rates and had nitrogen applied at different rates.

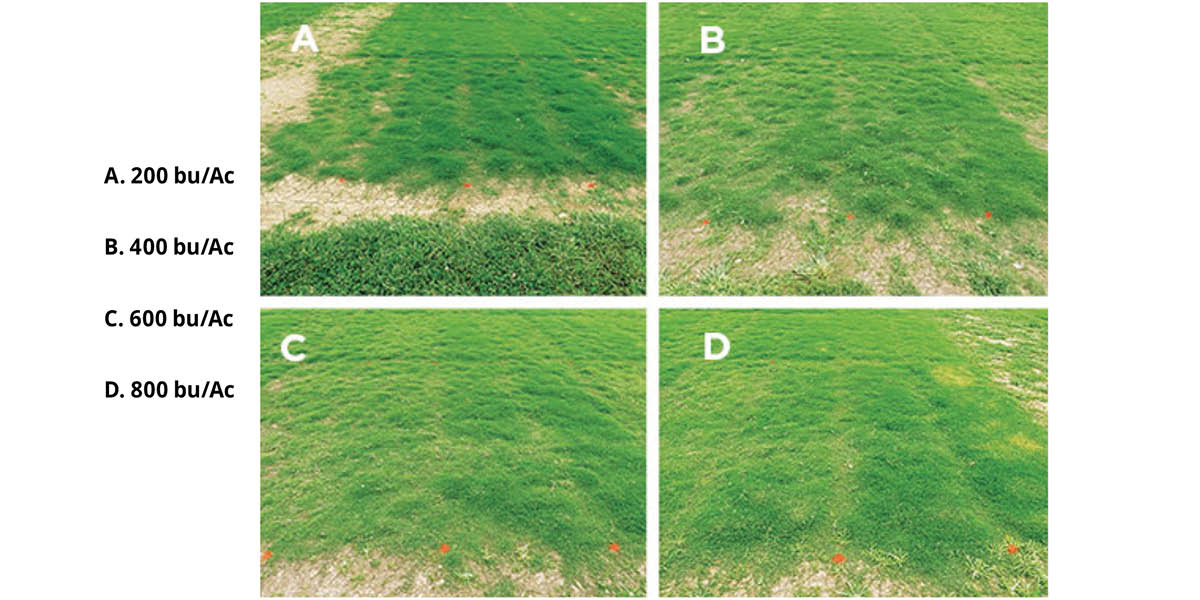

Latitude 36 Bermudagrass was sprigged at a rate (from medium to high) of:

Figure 2: Sprigging rate vs Nitrogen rate.

Four weeks (fast growing time) after sprigging, the trial plots that looked the best were C or D.

Fertiliser application on each block, from left to right kg/ha/wk of the block, was 0 – 12 – 24 – 48 kg/ha/wk.

Gregg summarised that the higher sprigging rates resulted in quicker cover and not necessarily the higher fertiliser rates.

“Which means if you are a sod producer selling sprigs do you want to produce higher volumes so the turf fills in quicker,” he added.

Looking at Table 1’s Sprigging rate v Nitrogen rate. (below)

Across the different N rates…

- 1 week after planting when assessing the different N rate applications and the different sprigging rates, all the plots have the same colour and percentage coverage.

- 4 weeks after planting, the plots with no N have 87% coverage and the plots with the highest N rate only a 7% increase in coverage (with 48kg/ha/wk). In short, a lot of fertiliser but not a significant increase in coverage.

“So just a little bit of fertiliser is performing the same thing as a lot of N, and you are not getting that ‘bang for your buck’ when you apply more N,” Gregg stressed.

“More is not necessarily better. Realistically, based on the above trial, it would be better to apply N between the 12 – 24 kg/ha/wk rate.”

Looking at Table 1’s – Sprigging rate v Nitrogen rate .

Across the different Sprigging rates…

Across the different Sprigging rates…

- 1 week after planting – across the different sprigging rates you have low cover (20%) to high (41%). This is not surprising as there are more sprigs at rate of 800 bu/Ac.

- Moving into four weeks the sprigging is increasing, as expected, however typically the higher rate (800 bu/Ac) has 20% to 30% more coverage in week 2 and 3.

ARE WE SEEING MASSIVE IMPROVEMENTS IN COVERAGE?

At times– but Gregg said that once you reach the 4-week mark there is not a massive difference because Couch (Bermudagrass) is a good grower and starts to fill in.

However, Gregg stressed that during the early weeks it was possible for the soil to start sprouting weeds on the low sprig coverage plot.

“So, the more cover you have on that plot, the less weed pressure just another benefit of planting at high sprigging rates,” he said.

In short, the learnings from the above trial are:

- At higher sprigging rates the turf fills in faster meaning less weed pressure.

- Less turf coverage causes higher soil losses especially after rain– therefore the more turf in the ground the better it will hold the soil.

- What about Nitrogen Use Efficiency (NUE)? Less coverage means much of the N application runs off.

Other studies in the US have reflected the same results as the data above. (Rice et al., 2019)

- High sprigging rates result in faster Bermudagrass establishment.

- High and low N rates result in similar Bermudagrass establishment.

- High sprigging and low N rates reduce nutrient losses during establishment.

WHAT ABOUT CONTROLLED RELEASE IN NITROGEN?

Gregg explained that soluble applications can result in N losses.

“Urea is great product but soluble –the plant initially uses some of the applied Urea but losses a lot through leaching and volatilization if it is applied at high quantities.”

SPOON-FEEDING OF SOLUBLE PRODUCTS CAN REDUCE NITROGEN LOSSES

Gregg said that such a process could occur weekly, but it would be costly in terms of labour and fuel.

CONTROLLED RELEASE OF NITROGEN FERTILISERS

“Following large applications, the fertiliser is released slower over a longer period of time,” he said.

“However, there is the possibility of N loss due to leaching and volatilization, and you do have high initial costs”

SOIL HEALTH

Figure 3: Soil components with overall averages.

Soil health is receiving a lot of attention these days from growers, councils, consumers and even governments.

Soil health is receiving a lot of attention these days from growers, councils, consumers and even governments.

Gregg said that soil health was one area that production agriculture had embraced – but there had not been much change in the Turf World.

BENEFITS OF GOOD SOIL HEALTH ARE:

- Increased water infiltration and storage – vital during dry or drought years. Want water stored in soil not running off.

- Reduced erosion.

- Healthier plants – a good balance of nutrients reduces disease.

- Increased nutrient storage and supply to plants. The physical, chemical and biological status of your soil has to be just right for it to be balanced.

- Carbon sink – healthy soils hold more Carbon Dioxide (CO2).

- Sustained life and society – soils would not be sustainable if we were to maintain old farming practices.

FINALLY, soil test reports are critically important and significant in keeping costs down.

When receiving the soil test results look for:

- pH (or water pH) most grasses you want in the 6-6.5 pH range.

- Soluble Salts Electrical Conductivity (EC) if higher than >4 dS/m – you have so much salt in soil that the salt holds onto water and the plant roots cannot absorb the water. SAR >12 if higher than 12 – sodium is a cation +1 as soils are negatively charged it causes deflocculation and the soil’s structure falls apart.

- Nutrient levels – N requirements are based on the plant’s needs.

- Organic Matter (OM) as much as 2/3 Ib N/M (32kg/ha) per 1% of OM is released into the soil solution by microbial mineralization each year.

WHY pH MATTERS

Because the majority of the nutrients that the turf requires are available in the 6-6.5 range (N, K, P, S, Ca and Mg). It is the same for microbes.

MICROBES

Microbes are about the size of a raisin and improve soil structure, aeration and the cycling of essential nutrients (Carbon, Nitrogen, Phosphorus, Sulphur). They also regulate the quantities of N available to the turf.

In short, microbes in your soil need:

- Organic Carbon

- Moisture

- Aeration

- pH neutral

- Temperature

- Inorganic nutrients

“So how do you maintain profitability while costs are sky rocketing?” Gregg once again asked.

“You look at all your inputs (discussed above) and adapt – review the areas of your business where you could cut back in terms of work or budget?”

Remember it is all about Getting More for Less!

ENDS

Fast Facts about the US Turf Industry

- There is 31 million acres of irrigated turfgrass in the US.

- There are 1465 sod farms in the US.

- The most common grass grown in the US is Kentucky Bluegrass.

- Kentucky Bluegrass got its name from the vast fields of blue grasses in Kentucky.

- Dr Gregg Munshaw’s favourite grass is Bermudagrass because it “absolutely will take a beating – such a tough grass that covers very well”.

ENDS

Background … Dr Gregg Munshaw

Gregg has 25 years of direct turfgrass experience, having worked on golf courses, athletic fields, and in teaching, research, and extension positions at Mississippi State University and the University of Kentucky. His research and extension programs align closely with the A-LIST’s mission of reducing inputs while providing quality turf.

As Director of Agronomy at Pinnacle Ag Research Centre, Gregg reviews Mountain View Seeds products while also developing better turf genetics for the future. There is no doubt the road forward for the turf industry is going to be tough. Production of turf will become more difficult with increasing levels of restriction on the use of chemicals and fertilisers.

Gregg recognises that genetics is the next great avenue to provide better turf varieties and plants that require fewer inputs, such as fertiliser!